1) Once upon a time in America

Before we move to the story of how Fila democratised access to its Carbon-Kevlar plate technology, it should be recognised that it was Brooks who created the first ever commercially available running shoe equipped with full-length carbon-fibre plates. During the eighties and leading into the nineties, Brooks were experimenting with many ideas to try differentiate themselves from the competition, but one was particularly revolutionary. Brooks dubbed the technology the Propulsion Plate System.

The carbon-fibre plate at the centre of the concept was flat and specially shaped to taper towards the rearfoot, mounted below the midsole foam and just above the outsole. This was broadly similar to what Fila would eventually do with their Carbon-Kevlar plate-equipped series of running shoes that first commercially launched in 1997 with the Silva Racer after appearing in prototype form in various races during 1996.

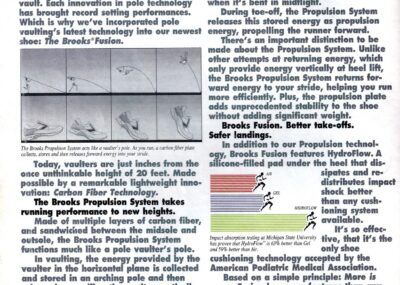

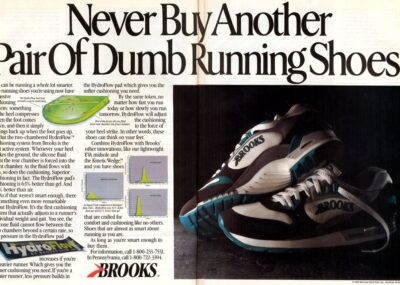

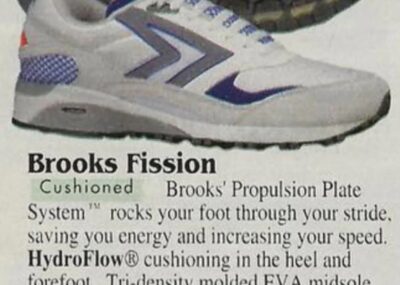

Advertising by Brooks was explicit as to the benefits of the Propulsion Plate System, describing how it helped propel runners through their gait cycle as the carbon-fibre plate flexed and rebounded just like modern running shoes with the same technology.

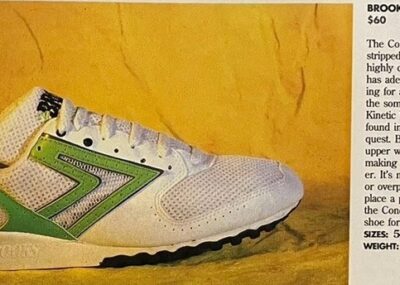

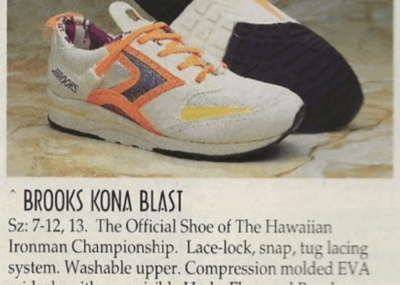

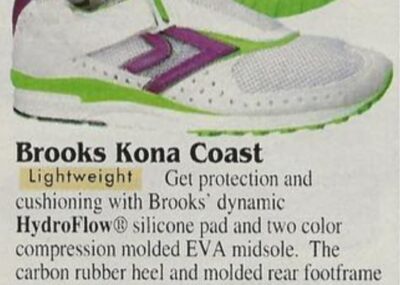

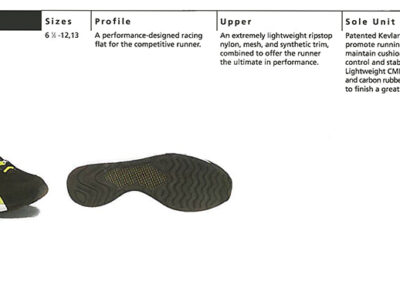

Will Albers was one of Brooks lead designers at the time, and in my correspondence with him confirmed that there was unfortunately never any real interest or motivation to take the Propulsion Plate System racing. Albers designed the Conquest, which was a traditional and effective racing flat weighing in at 170 grams, as well as the 210 gram Kona Blast that first launched in 1990 and included an upper more suited for triathlon racing (allowing the shoe to be put on quicker during these extremely gruelling competitions) as well as HydroFlow cushioning (more on that later).

Both models had co-moulded midsoles and outsoles, which saved crucial weight but meant that they would have needed considerable re-design to include the Propulsion Plate System. As it was, the Conquest and Kona Blast were more than competitive enough without needing to risk inclusion of the technology.

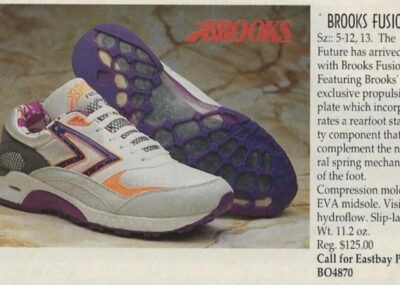

Brooks took two models to market for 1991 with carbon-fibre plates, the flagship Fusion with the Magnum alongside. Coming in at 317 grams Fusion combined the Propulsion Plate System with all of the latest technologies that Brooks had at the time including HydrowFlow cushion.

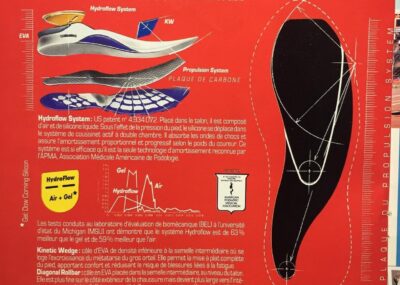

Introduced back in 1989 in several models including the GFS 100 pictured here, HydroFlow used silicone fluid in two connected chambers that forced the material forwards during the gait cycle. Testing suggested this was much more effective at absorbing impacts than the gel technology employed by ASICS as well as Nike Air. As we know more today, effective cushioning is the key to making carbon-fibre plate running shoes work most effectively.

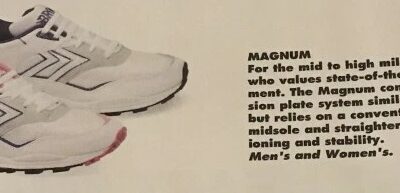

Providing a simpler and lighter alternative was the Magnum, which paired the carbon-fibre plate with a simpler ethylene-vinyl acetate (EVA) midsole.

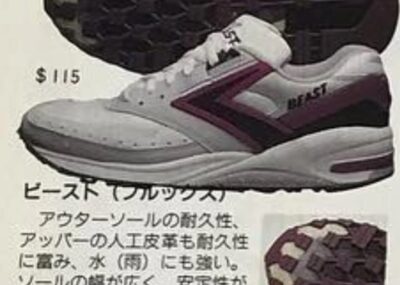

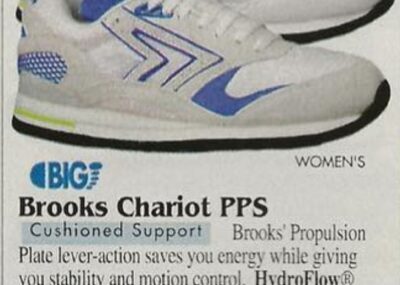

For 1992 Brooks would introduce three new models with the Propulsion Plate System. Heaviest of the range was the 355 gram Beast, designed to provide maximum cushion and pronation support. Part of this was the diagonal rollbar, designed to provide more gradual support for pronating. Although the Propulsion Plate System was designed to make running more efficient, the carbon-fibre plate also helped provide stability. For those looking for less weight while keeping both cushion and support there was the Mojo.

Simplifying the formula from the Fusion, the Mojo kept both the Propulsion Plate System and HydroFlow cushioning but retailed slightly cheaper making it one of Brooks most popular models. It should be noted all of these models, even the Conquest and Kona Blast, relied on EVA foam for cushioning.

2) Big in Japan

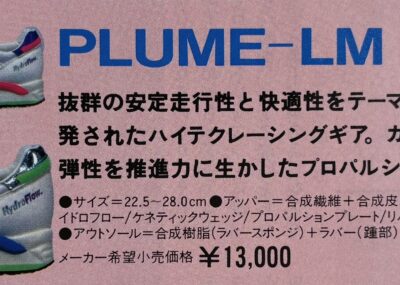

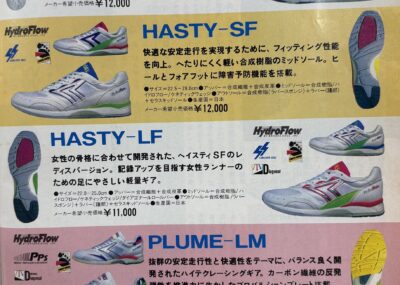

As flagged earlier, there was a fifth model using the Propulsion Plate System, the mysterious 1992 Plume LM. Firstly, I must thank @Mac.Oto on Instagram who provided the Brooks advertisement you can see here. Even Brooks have no record of the model in their archives, including via their Japanese office.

Although not pitched as an elite racing flat, instead being suitable for amateur racers as well as faster training paces, the Plume LM had the same ingredients as the Fusion but in its most streamlined form yet. Firstly there was the upper that was quite similar to the Brooks Hasty RF, a traditional racing flat also marketed for the Japanese market, which would have kept weight down.

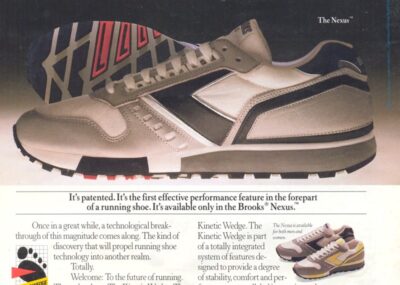

Beneath this was the same carbon-fibre plate and HydrowFlow cushion, as well as another innovation from Brooks called the Kinetic Wedge. Having been used in several models since the 1986 Nexus, it was in effect a specially designed wedge beneath the foot to help relieve pressure on the toe joint.

Given the expense and complexity of the technology, and considering that Brooks frankly had an otherwise extensive range of running shoes, the Propulsion Plate System only lived on until 1993. This was in the form of three more models, the Beast continuing on for one more year before it was updated for 1994, losing the Propulsion Plate System in the process.

First there was the Fission, a slightly updated version of the Fusion from the previous year. Providing an alternative to the Beast was the Chariot PPS, which in my understanding was designed for runners looking for pronation support but not to the extent provided by the Beast while still providing HydroFlow cushion and a similar diagonal rollbar for added support. The Plume LM also continued on for one more year in the Japanese market.

Finally, Brooks would take the Propulsion Plate System to basketball courts in the form of the Lightning PPS which continued on until 1994, but more on that later.

As far as I am aware this was the end of the line for the Propulsion Plate System. Interestingly, the Kona Coast (the sequel to the Kona Blast) triathlon racing shoe shared some visual similarities with the Plume LM. It also increased weight to around 245 grams with an upper making the shoe even more suited for being quickly put on during triathlons, but one has to wonder whether Brooks could have created a PPS variant of the Kona Blast that weighed around the same if not slightly less than the official sequel to the model.

There is also the fascinating unanswered question of what might have happened if the Plume LM was marketed in other markets for racing use, or even had its upper replaced with one from the Hasty RF or Conquest to create an entirely new model. Weight would still have been something of an issue, but clever packaging could have kept this key statistic competitive. Brooks could have also taken the same approach as the Mojo and only used EVA foam with the carbon-fibre plate, losing HydroFlow to keep things simpler and lighter.

It was not until the Hyperion Elite released by Brooks in 2020, having first raced in prototype form at the 2018 Boston Marathon, that the company would again make running shoes with carbon-fibre plates. Unlike the flat carbon-fibre plate used in the early nineties by Brooks, the carbon-fibre plate in the Hyperion Elite was curved to further enhance the effect of the technology. The potential of the Propulsion Plate System was definitely there, but as history shows it was Fila who would be the first to unleash it.

3) Win on Sunday, sell on Monday

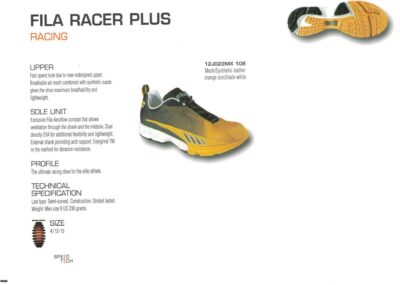

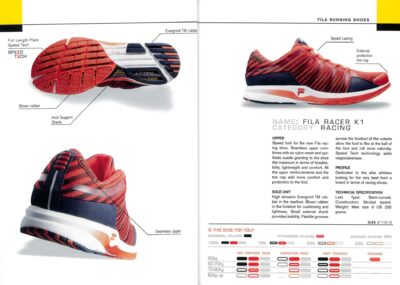

During the late nineties until the early noughties, Fila were one of the dominant forces in elite distance running. You can read more about this time in my article on Marathon Handbook, but in short they produced the first racing flat with carbon-fibre plates (Carbon-Kevlar to be specific): from the Silva Racer, Racer, Racer Plus, Racer K1, and the Racer K4, Fila captured countless victories in international distance running.

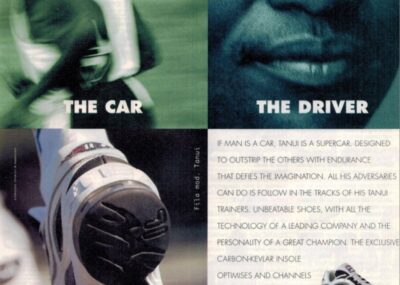

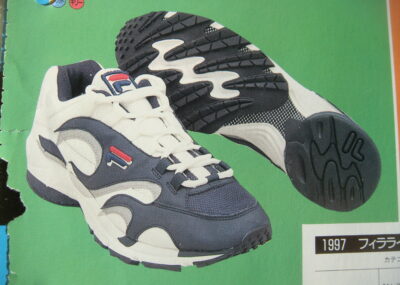

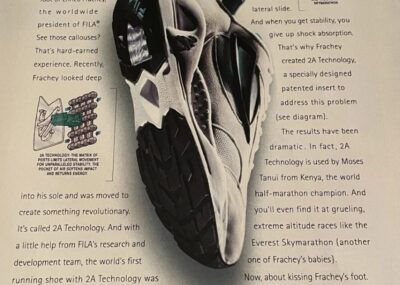

What however of the motorsport adage coined by Ford luminary Bob Tasca of ‘win on Sunday, sell on Monday’? Fila were acutely aware of this, and while developing the Silva Racer were preparing to put the exact same Carbon-Kevlar plate into something more usable for the everyday runner. They would release the Tanui in 1997. Named after the legendary distance runner Moses Tanui, who at that time held the half-marathon world record, it was the training companion to the Silva Racer. It had a much higher stack height, EVA foam with the 2A cushioning system developed by Fila under the rearfoot.

To explain further, 2A cushioning used ambient air with small plastic pillars to absorb shock and improve stability. This is somewhat different to Zoom Air as used by Nike, which contains an inert gas, although both technologies improved rebound as well. It also means that the Fila Tanui had arguably the same ingredients as the Nike Air Zoom Alphafly series, just in a far more accessible formulation.

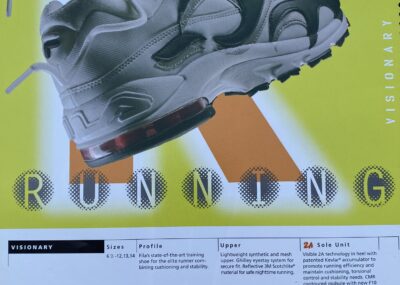

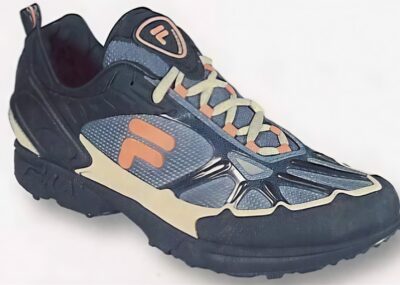

Finding information about the Tanui was basically impossible, and to confuse matters further Fila released the Visionary around the same time. It used the same midsole and outsole tooling, including the Carbon-Kevlar plate technology, as the Tanui. Its upper however took many visual cues from the Silva Racer upper, which makes it likely that it too was designed by Kevin Crowley. Unlike the neon yellow and red of the Silva Racer, the Visionary was comparatively more subtle with navy flames against the light grey upper.

Little is known about the Visionary other than the catalogue images I have been provided with. Even Filippo Pavesi, the brains that helped propel Fila racing shoes to such success, was not fully aware of the Visionary until interviewed for my Marathon Handbook article on Fila and their Carbon-Kevlar plate racing flats.

4) Because it’s there…

Since 1993, Fila had begun exploring the marketing potential for taking its products onto trails around the world. This was exemplified by their sponsorship of the Tibet Top SkyMarathon, the race starting at base camp for the highest peak in the world: Mount Everest, known locally as Sagarmāthā in Nepal and Qomolangma in Tibet.

These events pushed athletes to their limits at altitudes of well over 4,000 metres, and also allowed scientic testing of how their bodies reacted to the extreme conditions. On a sidenote, Matt Carpenter (who won several of these races) has uploaded videos chronicling several of these incredible races which you can watch on his YouTube channel.

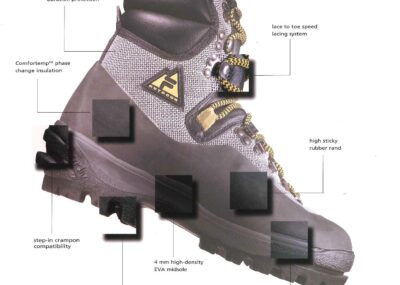

Another major advantage of Carbon-Kevlar was that it was incredibly strong while also remaining lightweight. Fila saw the potential to put this material inside of mountaineering boots, which needed to be stiff to be able to mount crampons. To achieve such rigidity, such boots would normally have to be quite heavy. Launching the Fila Outdoor brand in 1997, they were looking to take on the likes of Nike and Adidas as well as more traditional trail shoe brands.

Come 1998, Fila would release the Aguirre. Looking like an otherwise conventional and stylish mountaineering boot, it boasted a Carbon-Kevlar reinforced shank in the midsole. Very different in design to what was being used for the Silva Racer, it provided great strength to the boot while reducing weight compared with the metal shanks used by some other brands.

The concept itself was not entirely new, with Asolo launching its AFS-101 alpine mountaineering boot in 1986 which also featured a carbon-fibre shank to help aid rigidity. The Fila Aguirre however was designed to be used in many conditions and not just snow and ice like the Asolo. Carbon-Kevlar was also a significant improvement over pure carbon-fibre as Kevlar added durability. The setup Fila used also meant that further reinforcement was not needed, unlike the Asolo which used its hard nylon shell upper for added rigidity.

Unfortunately Fila did not produce a sequel to the Aguirre that I’m aware of, focussing instead on more conventional albeit highly competent hiking equipment without Carbon-Kevlar plates. There was however the racing oriented SkyRacer in 2000, which you can read more about in my article on Marathon Handbook. While released with a conventional upper, prototypes were made with an integrated gaiter. More significantly it used the split plate setup from the 1999 Fila Racer, and was the first trail racing shoe with carbon-fibre plates.

As you just read, Fila did not use a full-length Carbon-Kevlar plate for the Racer, having almost dropped the concept entirely for the model. The split system was only included after senior management intervened and put Filippo Pavesi onto the project at the last moment, one of the early signs of the dysfunction beginning to creep into Fila. It also meant that there was no immediate sequel to the Visionary. Their next training shoe with the plate technology would not release until 2001.

5) The Need for Speed

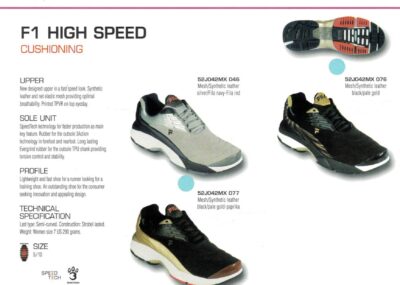

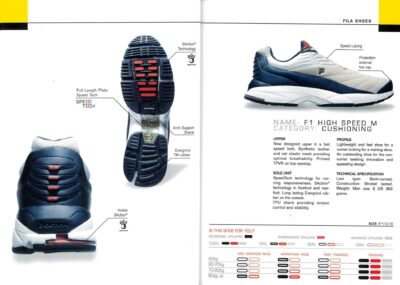

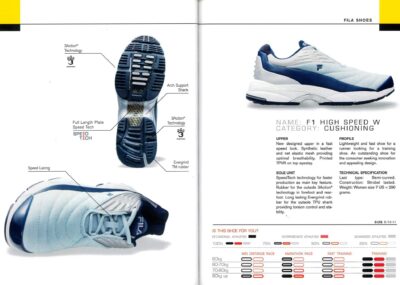

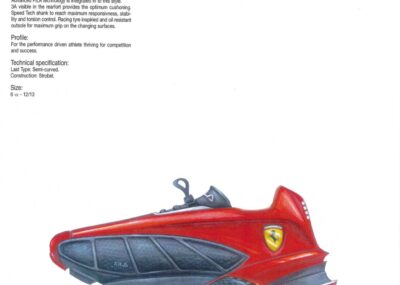

It was called the F1 High Speed, Fila putting the Carbon-Kevlar plate into the existing F1 model that released in 2000. Both models featured distinctive motorsport styling thanks to the talents of Stefano Favaro, who joined Fila in 1998. Runner’s World were positive in their review, saying the Carbon-Kevlar plate gave the ride smoothness and added propulsion. Cushioning was also praised, with the F1 High Speed featuring 3A cushioning, an update of the 2A cushioning system, using elastomer to improve on overall performance.

Weighing 365 grams, it was heavy but not unusually so for the time, in fact lighter than the original F1 which came in at 370 grams. With Fila featuring on the podium at countless major international marathons, it was clear the opportunity was there to further democratise the SpeedTech system, as Fila now called the Carbon-Kevlar plate technology. It should be noted that the F1 High Speed likely has a full-length plate based on images of the outsole, despite the Fila Racer and Racer Plus using a split plate (as before, you can read more about that fiasco in my article on Marathon Handbook).

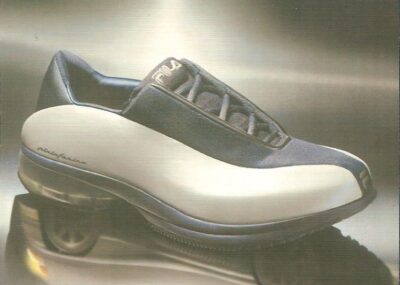

Alongside the F1 High Speed, Fila would release an even more explicitly motorsport-inspired shoe designed by Motoki Yoshio who specialised in transportation design. Called the Pininfarina, after the famous Italian coachbuilder, it had large uninterrupted swatches of leather to further enhance its automotive appearance. Beneath the upper was an extensive Carbon-Kevlar plate, although it is unclear whether it was more for show than outright performance.

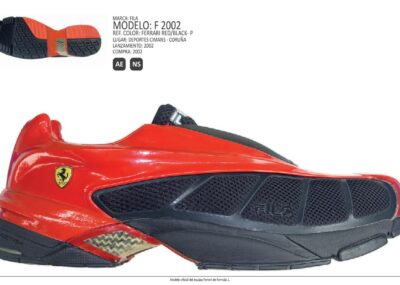

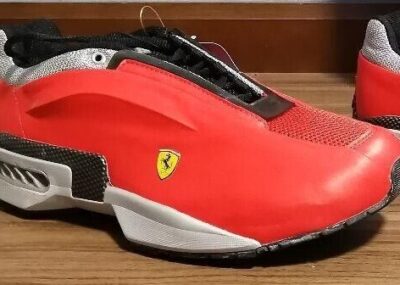

With Fila signing on to sponsor the Ferrari Formula One team in 2002, it was with little surprise when they released the F2002 which was also penned by Favaro. Named after the car in which Michael Schumacher would dominate Formula One with that year, it featured its own Carbon-Kevlar plate like the Pininfarina. Although the F2002 featured 3A cushioning, it was positioned more for fashion than performance

6) Hoop dreams

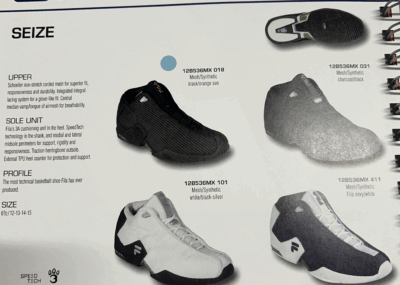

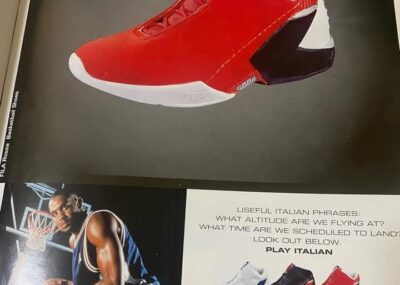

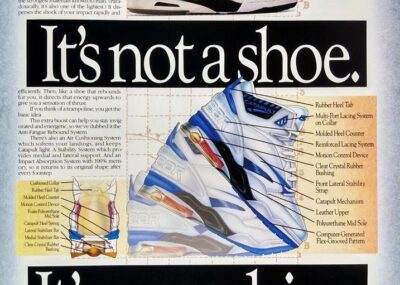

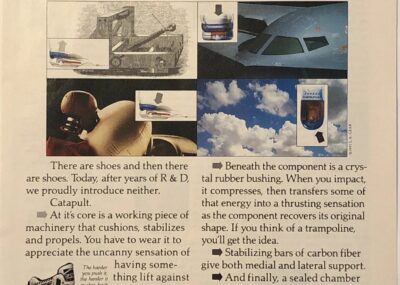

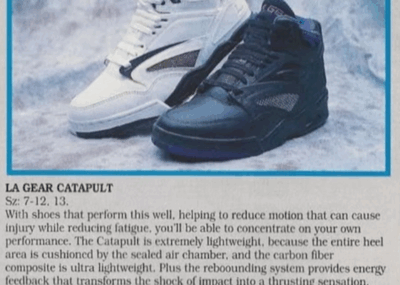

SpeedTech would also find its way into basketball courts courtesy of the Intake, Seize, and Rossa models released between 2000 and 2002. The Seize and Rossa used Carbon-Kevlar to make the shoes stable during the rapid movements required for elite basketball competition. To be clear, this was not by any means the first time either carbon-fibre or plates were used in basketball shoes to aid performance. All the way back in 1991 L.A. Gear were working hard to create basketball shoes that pushed the technological envelope so that their brand could be taken more seriously.

This lead to the Catapult, using what was dubbed the Power Feedback System. At the centre of this was a carbon-fibre lever under the heel which was shaped to bend under impact and then spring back into shape. It promised the ability to jump higher compared to its competitors. Unfortunately the technology did not survive long, L.A. Gear getting involved in legal disputes with Nike over patent infringement.

While the Power Feedback System would continue for 1992, L.A. Gear as a company would face considerable financial difficulties, filing for bankruptcy in 1998. L.A. Gear apparently still managed to release an updated version of the technology dubbed the Twistapult for 1993, however apart from the logo included in this article I have been unable to find any further information on this mystery basketball shoe.

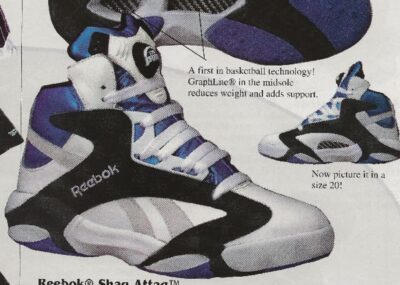

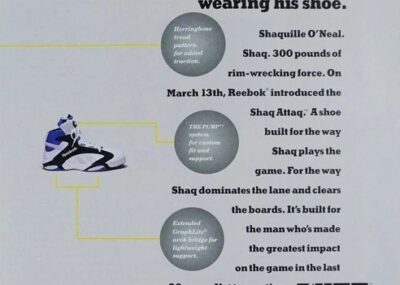

1992 would also see the launch of the Reebok Shaq Attaq, designed specifically for the needs of rookie and future basketball legend Shaquille O’Neal. It had within the midsole a graphlite plate that extended from the heel until just before the toes would flex. It was designed to provide stability for the 7-foot-1-inch center.

As flagged earlier it was Brooks who would be the first to release an elite basketball shoe with a full-length carbon-fibre plate. It debuted in 1993, another fascinating and obscure entry in Brooks history.

Named the Lightning PPS, it also featured HydroFlow cushioning to create a technologically sophisticated entry into the sport. It would continue being produced for 1994, but the Propulsion Plate System was dropped in favour of more conventional technologies from 1995 onwards.

As for Fila, Carbon-Kevlar was specifically used to create the shank as well as in the medial and lateral midsole perimeters i.e. making sure the foot would not roll either way, helping the player avoid injury. In both instances this was further reinforced by noticeable Thermoplastic Polyurethane (TPU) heel counters to provide additional lockdown.

Arguably the most interesting model of the three was the Intake. Based on images of its outsole and the description in the Fila catalogue provided to me, the Intake featured a full-length Carbon-Kevlar plate. The catalogue itself says that the Intake had “a SpeedTech plate running throughout the midsole for rigidity and responsiveness”.

This was highly unusual given the use of carbon-fibre in basketball shoes was generally more along the lines of the Sieze and Rossa to provide further stability, with some notable exceptions such as the Air Jordan XI. It would appear the plate setup in the Fila Intake managed to avoid rules set by the National Basketball Association that ban shoes giving an undue competitive advantage. L.A. Gear, Reebok, and Nike similarly avoided bans for their use of plates, carbon-fibre or otherwise.

Unfortunately there is no further information about these fascinating Fila basketball shoes, noting that Grant Hill wore the Intake and Seize (I was unable to find images of him competing in the Rossa). Given his significant injury woes at the time (unrelated to his wearing of Fila products) there was little opportunity to showcase any of the benefits of the various implementations of Carbon-Kevlar.

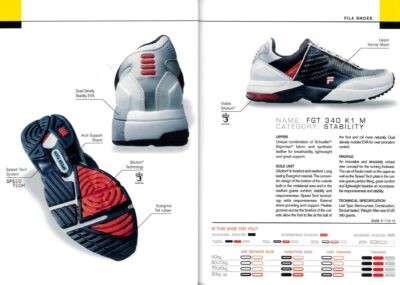

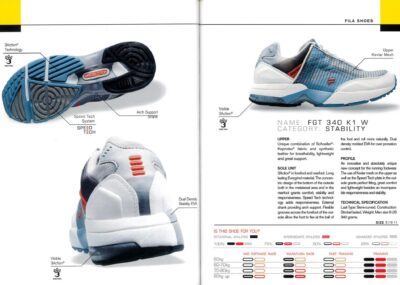

7) The FGT series

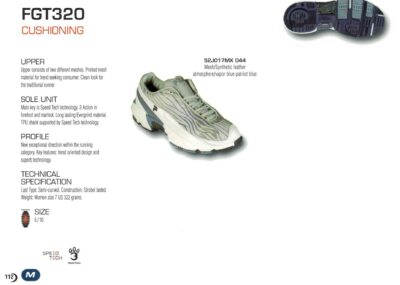

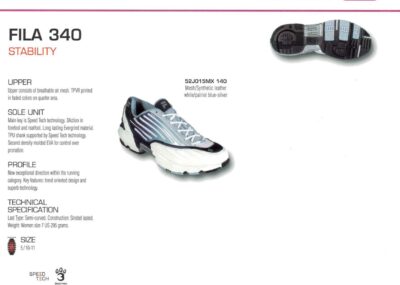

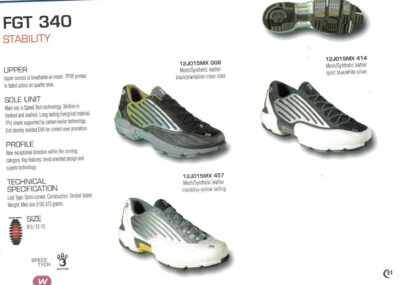

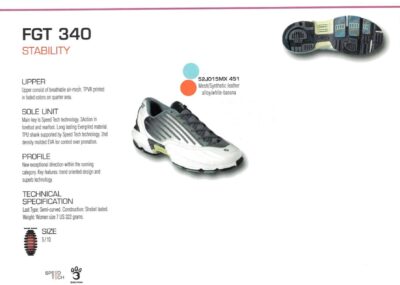

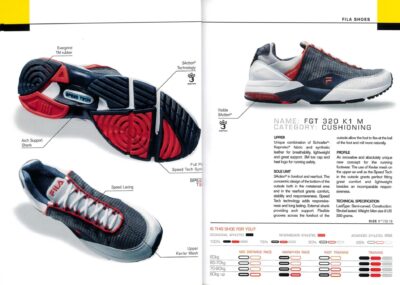

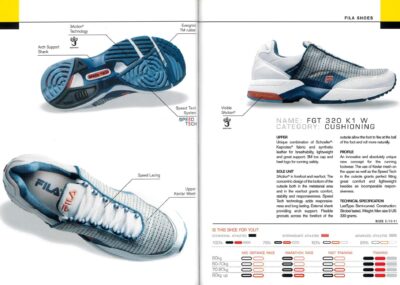

Giving runners more options were the FGT 320 and FGT 340 models for 2002, Favaro giving them their unique designs. Given the timing of release, they likely featured the same full-length plate featured in the Racer K1 that debuted the same year. The FGT 320 was designed for neutral runners while the FGT 340 was for those requiring more pronation support. Like the F1 High Speed, which was still available alongside the newer models, they used 3A cushioning. Both weighed slightly less than the F1 High Speed, 350 and 360 grams respectively.

Both the FGT 320 and FGT 340 reviewed well, Runner’s World more effusive in their praise about the propulsion given by the plate, particularly when running at faster speeds. Building on this positivity, in 2003 Fila would release updated versions of both models with the K1 moniker added on as well as softer foam to reduce the harshness of the plate. Weight would also drop, the pair now down to 330 and 340 grams each.

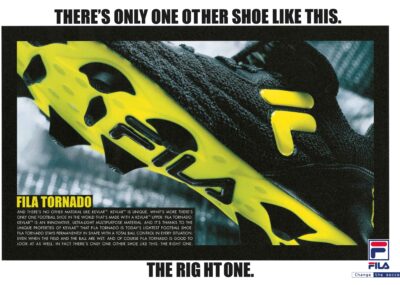

More significantly was the introduction of Kevlar fabric to the upper of both the FGT 320 K1 and the FGT 340 K1, joining the Carbon-Kevlar within the midsole. Using the specific version created by Schoeller Textiles, it was lightweight and extremely durable. The fabric was also relatively soft, making it perfect for running shoes. This was not the first time that Fila had used Kevlar to make uppers of athletic footwear. In 1998 they released the Tornado football boot, called the Fascino in other markets, which used the material to give added strength while reducing weight compared with more traditional materials.

Following from this were the Tornado II and Fascino II in 1999, both still using Kevlar material for their uppers but deviating in design with the Tornado II using leather to reinforce the sides of the boot around the midfoot. There was also the Ragnatela, or spider in Italian, which combined the fabric with a distinctive neon green web design. My understanding is that the model was released in 2000, and was the last hurrah for the technology before Fila focussed on more traditional products. It is not clear whether this decision was influenced by the management issues eluded to earlier that plagued the company during this time.

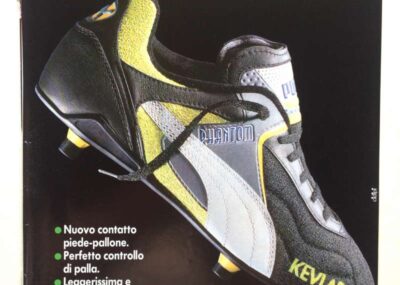

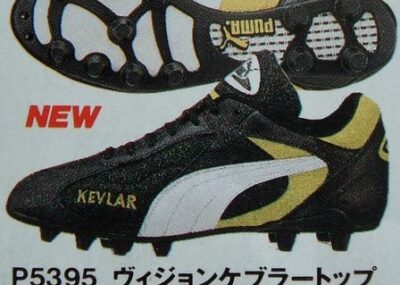

Interestingly it was Puma who was first to use Kevlar for football boots, the fabric also supplied by Schoeller Textiles, for the 1992 Phantom and the 1993 Vision. While benefiting from all of the characteristics of Kevlar, Puma appears to have quietly shelved the technology after these two models and focussed on other priorities. Many years later Nike would create an even more extreme take on the concept, the 2008 Nike Mercurial Vapor SL featuring an upper made entirely of carbon-fibre (as well as the outsole plate).

It took three years for Nike to develop, the overall result a reduction of 40 grams compared with their traditional football boots, the Mercurial Vapor SL weighing in at 186 grams. Given that the material would not have been particularly breathable, which would not have been a significant issue for use in football, any use of carbon-fibre for the uppers of running shoes would have likely been in combination with traditional fibres like the fabric provided by Schoeller Textiles.

8) Beginning of the end

Fast forward back to 2003, Fila were also beginning to look into potentially using Carbon-Kevlar for the upper of its running shoes, including the Racer series. These never left the prototype phase, I reached out to Schoeller Textiles to see if they had any more information on their work with Fila (including any shelved prototypes) but sadly they did not.

Had Fila incorporated every piece of technology available to them, including the Carbon-Kevlar upper, it might have looked something like this concept I created, the sadly fictional Fila Racer Evo. To further explain the design, given that elite distance runners primarily land on their forefoot and midfoot it would have likely neccesitated 3A cushion under the ball of the foot for it to be most effective, noting as well that the Carbon-Kevlar plate is mounted at the bottom of the midsole just like the Racer K1 and Racer K4.

2003 would also see Fila releasing the final evolution of the FGT series, the FGT 1000. Every lesson Fila and Favaro had learned from previous models was applied, resulting in a flexible daily trainer that was comfortable at slower paced but equally capable of picking up the pace. Although the foam of the time did not allow for the lightweight speed trainers we enjoy today, it still came in at an otherwise respectable 333 grams. Even so, Favaro commented in an interview that this was still heavier than he would have preferred.

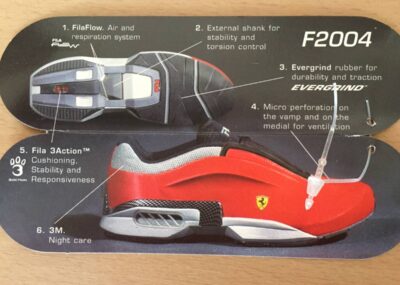

Fila would use the same midsole unit, complete with Carbon-Kevlar plate, for the F2003 model designed by Favaro as part of their sponsorship deal with the Ferrari Formula One team. While this would have made the model highly capable for running, the upper was primarily made of leather with little breathability. As with the F2002, the model was designed more as an artistic homage to motorsport. The F2004 model sadly had no Carbon-Kevlar plate at all, the only use of the material purely aesthetic as part of its upper.

Releasing in 2004, the final proper non-racing running shoe that Fila released with Carbon-Kevlar plates was the FGT 1000 K1. From what I can tell, the only change made compared with the FGT 1000 was to its appearance, the model retaining the same midsole as its predecessor. Just like the F1 High Speed, Fila were looking to differentiate themselves from other brands through radically different styling as well as their Carbon-Kevlar technology. Both models were so obscure that I had to use artificial intelligence to scale up images for this article (I used https://imgupscaler.ai/ to be specific).

While subjective, the originality of the designs is something to be applauded. Given the current interest in that era of running shoes, it is surprising the FGT series has not been brought back, even if this would mean dropping the Carbon-Kevlar plate. Unfortunately their distinctive styling may have contributed to difficulties at the time in cutting through what was and still is an incredibly competitive market, Favaro also commenting that Nike as an example had marketing prowess that Fila could not match.

The various FGT models would in some instances go on massive discount, the overall situation not helped by the aforementioned issues plaguing Fila management. The training shoes were all developed separately from the racing models spearheaded by Pavesi, the silos within Fila an unfortunate recurring theme.

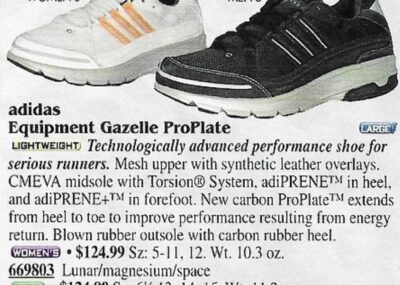

It was an ignominious end to what should have been a revolutionary series of products, only Adidas competing however briefly with the 2001 Equipment Gazelle ProPlate (and as discussed earlier, Brooks pre-dated both with their Propulsion Plate System models of 1992 and 1993). The Adidas shoe had a carbon-fibre plate shaped like a spoon, which would eventually be updated to underpin another highly significant running shoe.

9) The next generation…

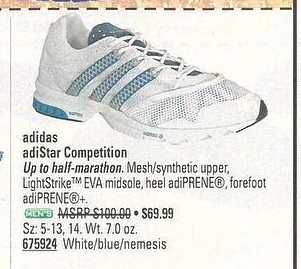

More than fifteen years would pass until Nike released the next series of running shoes making use of stiffened plates. It was primarily the creation of Dr Geng Luo, a student of Dr Darren Stefanyshyn who had designed the ProPlate that underpinned the Adidas Equipment Gazelle ProPlate and its racing counterpart the 2003 Adistar Competition.

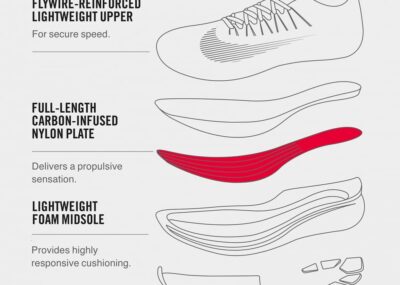

While the Nike Zoom Vaporfly Elite and Zoom Vaporfly 4% combined carbon-fibre plates and highly responsive polyether block amide foam (which Nike dubbed ZoomX) to create incredible racing shoes, there was as importantly the Nike Zoom Fly which was designed for amateur racing and faster training paces.

With the same geometry as the Zoom VaporFly 4%, but instead using a nylon plate (which was apparently reinforced with carbon-fibre) with an advanced formulation of EVA foam mixed with nitrile rubber that Nike called Lunarlon, it gave more runners access to the technological platform that Nike had development. It built on the foundations created by Brooks and Fila, paving the way for countless other companies to provide daily trainers with carbon-fibre (or other material) plates.

My thanks go out to everyone who helped with researching this period of running shoe history, in particular to the wonderful team at Fila Australia who were kind enough to provide the catalogue images that mostly illustrate this article and of course to Filippo Pavesi who gave up so much of his time to help me write my original article on Fila and their Carbon-Kevlar running shoes. As with that article, I hope this piece helps bring to light the history that laid the foundations for the technologically sophisticated running shoes we all enjoy today.

References

Marino Giacometti

Stefano Favaro

Will Albers

Dave Claflin

Steve Starr

Michael Robertson

Fila Australia

Fondazione Fila Museum

https://www.instagram.com/filippo.pavesi

https://www.instagram.com/eastbay.archive

https://www.instagram.com/trydar

https://www.instagram.com/ishicaru

https://www.instagram.com/mac.oto

https://www.instagram.com/vintageflorilege

https://www.instagram.com/spartan_harriers

https://www.instagram.com/seth.hematch

https://www.instagram.com/antonell07

https://www.instagram.com/kicksosaka_official

http://www.nosugar.co.uk/index.php

https://ameblo.jp/hasemako1414/

https://www.robertwbyrne.com/studio-history-2

https://www.ebay.com/itm/364959753411

https://www.ebay.com/itm/226918725541

https://www.ebay.com/itm/145390400073

https://www.ebay.com.au/itm/275090326875

https://www.ebay.com/itm/285876028334

https://www.myitalianbazaar.com/en/prodotto/20897/original-advertising-puma-september-1992/

https://smhc.co.uk/collection/pair-of-asolo-plastic-climbing-boots/

https://www.sdrunnersshop.com/blogs/blog/retro-advertisement-1989-brooks-hydroflow

https://bigwalls.net/climbingMagsJM/1987FebruaryClimbing.pdf

https://uspto.report/TM/74355590

https://www.ebay.com/str/runningmagazinesbooksmemorabilia

https://x.com/uniquesportshop

https://lorenzomariniassociates.com/

https://marathonhandbook.com/fila-carbon-plated-super-shoe/

https://www.roadtrailrun.com/2017/06/nike-zoom-fly-first-run-impressions.html

https://www.runnersworld.com/uk/gear/shoes/a760341/fila-f1-high-speed-pound59-99/

https://www.runnersworld.com/uk/gear/shoes/a760343/fila-fgt320-pound59-99/

https://www.runnersworld.com/uk/gear/shoes/a760344/fila-fgt-340-pound69-99/

https://www.runnersworld.com/uk/gear/shoes/a760350/fila-fgt340-fgt320-pound70-pound65/

https://www.runnersworld.com/uk/gear/shoes/a760836/fila-fgt1000-pound70/

https://www.runnersworld.com/uk/gear/shoes/a760300/adidas-equipment-gazelle-pro-plate-pound99-99/

https://c2creativity.com/

https://weartesters.com/inside-access-the-story-of-nike-lunarlon/

https://colnect.com/en/phonecards/phonecard/439727-FILA_2A_System-Advertising-Korea_Telecom-Korea_South

https://www.designweek.co.uk/issues/8-february-2001/adidas-serves-pro-plate-system/

https://youtu.be/Do24FLbA8uY

https://www.sdrunnersshop.com/blogs/blog/retro-ad-from-october-1986-the-brooks-nexus

https://runningmagazine.ca/sections/training/carbon-fibre-plate-tech-the-calgary-connection/

https://www.soccerbible.com/performance/football-boots/2020/05/remembering-the-nike-mercurial-sl/

https://www.marathonshoehistory.com/the-last-unicorn-adidas-and-the-adizero-sub2/